Source: Eddy Pump

Introduction

In industries like mining, dredging, and industrial waste management, handling highly abrasive slurries is a daily reality. These operations expose equipment to intense wear, demanding rugged and reliable pumping solutions. Among the most trusted options for such tough jobs are submersible slurry pumps. Designed to be fully submerged and to operate under extreme conditions, these pumps have become indispensable in high-abrasion environments. This article explores how submersible slurry pumps meet the demands of abrasive applications and what to consider when selecting one.

Understanding the Demands of High-Abrasion Environments

High-abrasion applications involve fluids containing hard particles such as sand, gravel, ore, or industrial waste. These particles are highly erosive, especially when suspended in a liquid medium. Traditional pumps often fail quickly under such stress, leading to frequent downtime and increased maintenance costs. This is where submersible slurry pumps excel—specifically designed to handle large solids and resist damage over extended periods of operation.

Why Submersible Slurry Pumps Are Critical?

Submersible slurry pumps are essential in demanding industrial applications due to their unique design and operational advantages. Installed directly within the slurry or sediment, these pumps eliminate suction limitations, enabling more efficient performance under heavy load conditions. Their fully submerged operation allows for higher efficiency in environments with high solid content, while also minimizing the risk of clogging and cavitation.

Additionally, submersible pumps offer a compact system footprint and enhance safety by reducing operator exposure to hazardous materials. These benefits make them a critical component in continuous-duty operations where reliability and uptime are paramount.

Key Challenges in Abrasive Applications

Working in high-abrasion environments poses several challenges:

- Impeller and casing wear: Constant contact with sharp particles can erode components quickly.

- Clogging: Large or sticky solids may block inlets or impellers.

- Heat dissipation: Slurry is typically thick, reducing the effectiveness of heat transfer.

- Corrosive agents: In addition to abrasion, many slurries contain corrosive chemicals that attack pump components.

Addressing these challenges requires selecting the right materials and engineering designs tailored for conditions to abrasive applications.

How Submersible Slurry Pumps Handle Extreme Wear and Tear?

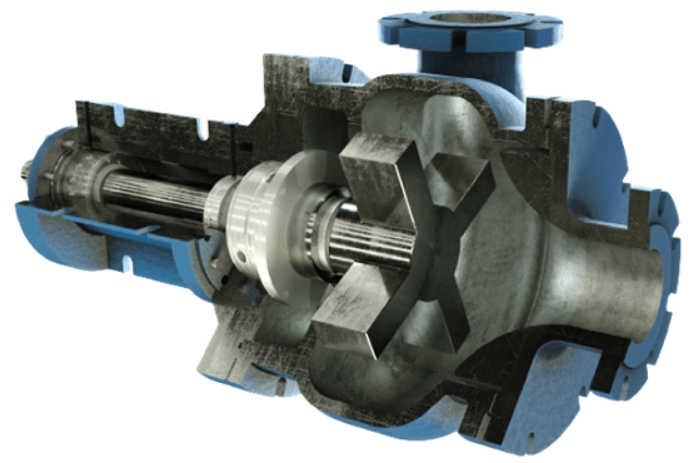

Submersible slurry pumps are specifically designed to withstand the extreme wear and tear associated with handling abrasive media. Their durability is achieved through several key engineering features. Hardened impellers and liners, typically made from high-chrome alloys or rubber, resist erosion and extend the pump’s service life. Oversized shafts and bearings offer increased strength and stability, ensuring reliable performance under demanding conditions.

Advanced seal protection systems prevent slurry from entering the motor housing, safeguarding internal components. Additionally, integrated agitators and cutters help break up settled solids, minimizing blockages and maintaining efficient operation. These combined features make submersible slurry pumps a reliable, long-term solution for tough industrial environments.

Impeller and Casing: Built for Abrasion Resistance

Two of the most critical components in any slurry pump are the impeller and the pump casing. In high-abrasion settings:

- Impellers are often made from high-chrome cast iron, which resists pitting and erosion.

- Pump casings are lined with replaceable wear plates or rubber coatings.

- Closed or semi-open impeller designs are chosen depending on particle size and density.

The design and material composition of these parts directly impact a pump’s lifespan and performance.

Top Applications for Submersible Slurry Pumps in High-Abrasion

Submersible slurry pumps find widespread use across various heavy-duty industries:

- Mining: Ore and mineral transport from pits and underground tunnels

- Dredging: Sediment removal in rivers, ports, and lakes

- Steel production: Handling mill scale and slag

- Tunneling: Managing spoil removal and groundwater

- Power plants: Removing fly ash and bottom ash in coal-fired stations

Each of these applications involves highly abrasive materials that require durable and efficient pumping systems.

Key Features to Look for in an Abrasion-Resistant Pump

When selecting an abrasion-resistant pump, it is important to focus on features specifically designed to handle abrasive media effectively and reliably. Key considerations include the pump’s material construction—options like high-chrome alloys, duplex stainless steel, or rubber linings offer enhanced durability against wear. An integrated agitator is beneficial for keeping solids in suspension, ensuring consistent flow and reducing the risk of blockages. Robust seal systems, such as dual mechanical seals or seal flush plans, provide additional protection in harsh environments.

A flow-through design further enhances performance by minimizing clogging and improving particle handling. Additionally, an abrasion-resistant pump with modular components and easy access to wear parts streamline maintenance and reduce repair times. Investing in a pump with these features can significantly decrease unplanned downtime and enhance the overall return on investment.

Optimal Hydraulic Design for Particle Handling

A well-designed hydraulic system improves a pump’s ability to handle slurry effectively. Key elements include:

- Wider passages: Allow large particles to pass through without obstruction

- Vortex action: Enhances flow and prevents clogging

- Low NPSHr design: Reduces cavitation risks and extends equipment life

The right hydraulic design enhances overall system efficiency, especially in operations requiring the movement of high volumes of slurry for abrasive applications.

Conclusion

Submersible slurry pumps are indispensable in high-abrasion environments, offering powerful, reliable, and efficient solutions for handling some of the toughest materials. By understanding their design, features, and ideal applications, industries can better equip themselves to meet the challenges of abrasive media handling. Whether you’re in mining, dredging, or any high-impact sector, investing in the right abrasion-resistant submersible pump is key to maintaining uptime, controlling maintenance costs, and optimizing operational performance.