Overview

Because of its affordability, ease of use, and speed, lateral flow assays (LFAs) have emerged as a vital diagnostic testing tool for point-of-care testing. Lateral flow tests are extensively employed in many different industries, ranging from COVID-19 tests to pregnancy kits and food safety inspections. The lateral flow strip cutter, a precise device that guarantees the uniformity and caliber of test strips, is an essential part of the manufacturing process for these tests. This article explains the definition of a lateral flow strip cutter, its function in the manufacturing process, and how a top-notch cutter may maximize output.

A Lateral Flow Strip Cutter: What Is It?

Laminated test sheets can be divided into separate test strips using a specialized machine called a lateral flow strip cutter. Because they include the test and control lines that give the user data, these strips are crucial to the operation of lateral flow assays. Extreme precision is required throughout the cutting procedure since improperly cut strips may result in uneven results, higher rejection rates, or even faulty tests. Because of this, producers in the diagnostics sector spend money on high-performance cutting devices that provide uniform width, sharp edges, and little trash.

Function in Manufacturing Lateral Flow Tests

The sample pad, conjugate pad, nitrocellulose membrane, and absorbent pad are among the parts that are put together onto a backing card during the lateral flow test strip production process. The sheet needs to be cut into thin, separate strips, usually only 3–6 mm wide, when assembly is finished. This crucial task is handled by the strip cutter, which is essential for a number of reasons.

It guarantees accuracy by keeping the strip width constant throughout the batch; it speeds up the process by automating a laborious and error-prone manual task; it supports quality assurance by lowering the possibility of cross-contamination and test failure; and it increases efficiency by boosting production output while minimizing material waste.

Crucial Elements of the Perfect Lateral Flow Strip Cutter

Manufacturers should consider a number of important factors when choosing a lateral flow strip cutter in order to guarantee long-term dependability and high-quality output. High precision cutting is essential because consistent results depend on the cutter maintaining tight tolerances, usually within ±0.1 mm. The reliability of the test can be jeopardized by even small variations that alter fluid flow within the strip. Another essential feature is flexible width modification.

Which enables manufacturers to rapidly and effectively transition between various test designs. Clean, burr-free edges guarantee the integrity of the strip’s capillary action, while an automated feeding system speeds up production and minimizes user involvement. Last but not least, preserving hygienic standards in delicate diagnostic settings requires simple upkeep and cleaning, ideally with stainless steel surfaces and tool-free disassembly.

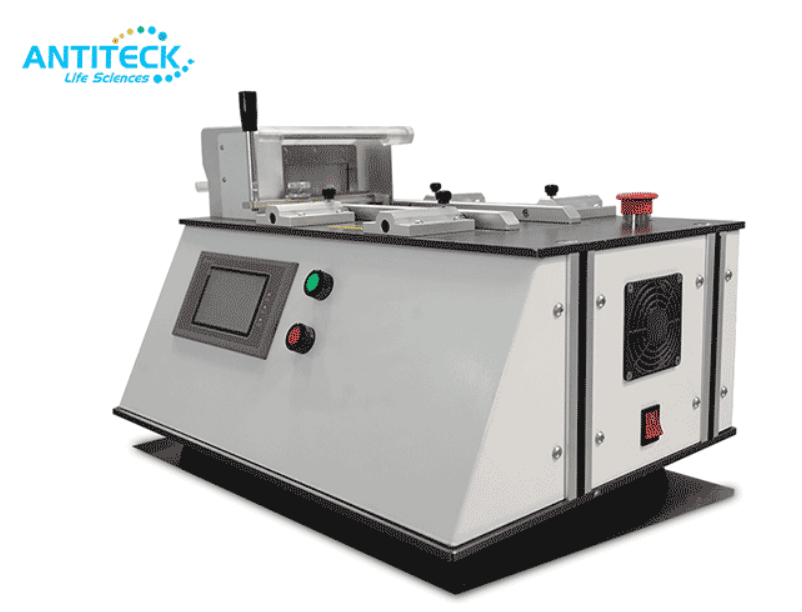

Why Select the Lateral Flow Strip Cutter from Antiteck?

At Antiteck, we recognize the value of accuracy in each stage of the production of diagnostic tests. In order to assist manufacturers in meeting strict quality standards, our Lateral Flow Strip Cutter was designed with precision, speed, and durability in mind. High-speed precision cutting that can support up to 100 cuts per minute while maintaining dimensional consistency; adjustable cutting widths ranging from 2 to 10 mm.

Minimal material waste because of the optimized design; an easy-to-use interface that requires little training; and a small, space-saving form that can be used in any production setting are some of the key features. Manufacturers may greatly increase productivity, test reliability, and overall cost-efficiency by utilizing Antiteck’s strip cutter.

Uses in a Variety of Industries

Many different businesses use lateral flow assays, and the efficacy of these tests is directly impacted by the quality of strip cutting. They are employed in medical diagnostics for drug screening, COVID-19, HIV, malaria, and pregnancy. They are essential to the quick identification of illnesses in dogs and cattle by veterinary diagnostics.

They aid in the identification of toxins, allergens, and pathogens in food safety, and they are used in environmental testing to analyze soil and water contamination. Because improperly cut strips can impair test accuracy and have major repercussions, accuracy and dependability are crucial in each of these domains.

Tips for Long-Term Performance Maintenance

Regular maintenance is necessary to guarantee your lateral flow strip cutter operates at its best and lasts a long time. Daily cleaning to get rid of material residue and avoid contamination, regular blade inspections with prompt replacements when needed, regular calibration tests to ensure cutting width and alignment, and updating the control system software are all advised practices. To keep your machine in optimal condition for the duration of its service life, Antiteck offers consumers comprehensive documentation and dependable customer assistance.

Choosing the Best Lateral Flow Strip Cutter in the End

Despite appearing to be a minor part of the entire manufacturing process, the lateral flow strip cutter plays a crucial role in guaranteeing both production efficiency and product quality. Precision cutting reduces waste and maximizes output by ensuring every test runs as planned. It makes sense for people who do lateral flow assays to spend money on a top-notch strip cutter like the one offered by Antiteck. It facilitates adherence to global quality standards in addition to improving production capabilities. Visit our special page on the Lateral Flow Strip Cutter right now to find out more or to get a price.